As e-commerce becomes a way of life, people across the globe are receiving more packages than ever. Thankfully, bubble wrap and the dreaded styrofoam packing peanuts are less and less common as businesses turn to bubble wrap alternatives. As a result, many companies are choosing sustainable e-commerce packaging solutions.

You’ve probably experienced this scenario before. A long anticipated package arrives. The box is a bit larger than expected, which is weird, but you push that thought aside and slice it open. You open the box to a sea of white packing peanuts. You dive your arms deep to find your goods as peanuts escape the box, scattering all over the floor. The single product you ordered is finally here, yet now you have an unexpected mess to deal with. You think to yourself, “What do I do with all these peanuts? Why’s the box so big?”

Fortunately, packaging is evolving. Even Amazon has issued new Frustration Free packaging guidelines with three main requirements: easy to open, 100% recyclable, and fully protective according to ISTA standards. Each of the options on the following bubble wrap alternatives meet ISTA protection standards and leave a smaller carbon footprint.

- Kraft Paper

- Honeycomb Kraft Paper

- Cardboard

- Molded Pulp

- Biodegradable Packing Peanuts

- Suspension Packaging

- Retention Packaging

- PLA Thermoform Trays

- PLA Air Cushions

- Paper Air Cushions

Kraft Paper

One of the cheapest and easiest solutions, kraft paper is as simple as cut and crumple. It comes in a roll, it’s usually made from recycled paper, and it’s easy to recycle in virtually every curbside program. Kraft paper gets the job done for most products, and companies can use the surface to print branding or messaging. As a sustainable packaging design agency, we use kraft paper in a majority of our packaging projects.

Honeycomb Kraft Paper

Imagine kraft paper that reproduces one of nature’s most advanced architectural wonders. The honeycomb structure stretches and expands, adding lightweight protection even for fragile products made out of glass or ceramic. Since this innovative material also comes in rolls, it’s easy to store on warehouse shelves and grab for convenient usage.

Honeycomb kraft paper is a type of corrugated bubble wrap. It functions just like plastic bubble wrap, but it’s 100% recyclable. And with the right equipment, you can make your own corrugated bubble wrap and take your sustainability to the next level. Recycling.com—a Dutch website teaching the world how to reduce, reuse, and recycle—explains how a cardboard shredder can transform cardboard scraps into free honeycomb kraft paper.

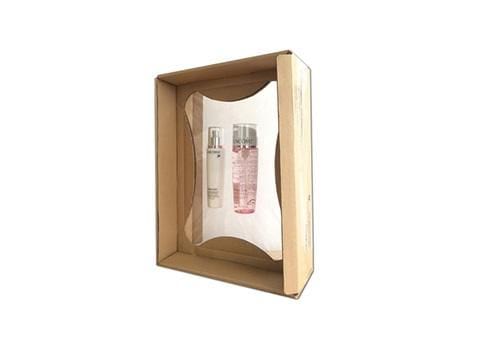

Cardboard

When it comes to protecting contents, cardboard is one of the most versatile materials out there. With the right package engineering, cardboard interiors provide unrivaled protection using only a few clever folds and cutouts. Engineering does take design time and money, but the long-term benefits are worth it. After a brief assembly, all that’s left is slipping the product into the custom cutout. And it’s a printable surface, so you can extend your branding to the interior. And it’s a printable surface, so you can extend your branding to the interior. Among other uses, it’s perfect to protect kitchenware packaging design.

Molded Pulp

Molded pulp has become an eco-friendly daily staple for just about everyone. Your morning eggs stay protected in molded pulp trays. Your drinks from the coffee shop stay secure in molded pulp holders. Even your iPhone comes in a pristine molded pulp tray. What do eggs, lattes, and smartphones have in common? Massive quantities are sold each day, so molded pulp makes sense for these producers.

It’s a simple process, but it can cost a few thousand dollars just to make the molds. As the name suggests, recycled paper pulp is combined with water and then poured into a hot vat where a CNC-routed molds designed specifically for the product is dipped into the slurry. It’s then pressed for a few minutes just like a giant waffle maker. If you’re selling high volumes of the same product, the up-front expense makes sense as the per unit cost of the finished molded pulp is fairly inexpensive. We use molded pulp in all kinds of alternative packaging applications, such as consumer electronics packaging designs.

Biodegradable Packing Peanuts

Made from starchy natural materials like corn, biodegradable packing peanuts were first introduced in the 1990s. Unlike other biodegradable packaging, you can be sure these actually break down. Just run them under water and watch as they quickly dissolve while emitting a smell reminiscent of burnt popcorn. For a cheap solution for light to medium weight products, stock up on biodegradable packing peanuts.

Suspension Packaging

Using only cardboard and a thin layer of plastic, this method actually suspends the product within the box to protect from impact as well as shifting in transit. It’s an effective solution for heavy products including electronics like cell phones, laptops, and tablets. The mechanism requires some package design to match the goods inside, but assembly is a breeze, and the cardboard-plastic can last for multiple shipments. You can further minimize the carbon footprint with biodegradable polylactic acid plastic film (PLA), derived from sugar cane or corn starch.

Retention Packaging

Just like suspension packaging, retention packaging protects products with strategically designed cardboard and a thin layer of plastic. It’s a popular choice for shipping wine and other glass bottles, allowing for slight movement to disperse pressure throughout the bottle and package.

PLA Thermoform Trays

From snacks and food containers to small parts and tools, thermoform trays are used in every industry that needs packaging. Inexpensive and easy to produce, they are made by heating a thin layer of plastic to the point where it can stretch and form to a custom mold, similar to the molded pulp process. Now that PLA is becoming more cost-effective, the biodegradable version is a viable solution for moving towards a more eco-friendly strategy.

PLA Air Cushions

Have you ever received a box with ciabatta roll shaped air bags? These little pillows go a long way in protecting goods, and they are now available in biodegradable PLA plastic. Fulfillment centers like the ease of air cushions because they store flat. Feed them through a specialized machine to puff them up as needed.

Paper Air Cushions

PLA air cushions are cheap, convenient, and effective, but ultimately, it’s still plastic. Even though they’re labeled as biodegradable, PLA plastic may require industrial conditions for proper breakdown. For a truly green alternative, there’s a kraft paper version. Most are made from at least 85% FSC-certified recycled paper and can be thrown away with curbside paper recycling.

But how does kraft paper stay inflated? The interior is lined with a thin plastic film made from biodegradable starch. Paper-PLA plastic combinations have been known to interfere with recycling streams, but this film is thin enough to quickly dissolve in paper pulp processing plants.

Eco-friendly Shipping: Something for Everyone

With so many bubble wrap alternatives available, there’s an option for every type of e-commerce business. When making the final decision, consider how much protection your products need, fulfillment time, shipping costs, branding placement, and of course, the customer unboxing experience. That’s all part of choosing a premium packaging solution. For more information, check out our recent blog on building an e-commerce packaging strategy.

If you want to know more about Zenpack’s services

Let our packaging consultants help you turn your idea into reality.