Although most businesses don’t ask for specific materials, there are obviously some types of packaging materials that Zenpack prefers more than others. But to understand why, it’s good to look at the common packaging materials frequently used in this space. And while Zenpack is a sustainable packaging company, it’s only fair to show everything currently in widespread use.

Will a little bit of bias show here? Oh, most certainly. And that’s fine, because in 2021, over 60% of consumers went out of their way to buy sustainably-packaged products. So although biases may be on the table here, your customers want the same thing—sustainable packaging, as waste-free as possible.

Before we get into this, we need to explain the use of “compostable” down below. While it should be clear, the term has been mishandled by many companies in recent years. Compostable means you can put it in your compost pile out back and it will disappear into new, healthy soil. It won’t leave any toxic chemicals or residues behind, and it will enable new plant growth.

Industrially compostable is a different animal, and may or may not be greenwashing depending on use case, but we’ll get into that more down below.

Another aspect of sustainability that should be mentioned is the use of monomaterials. This means using one type of material to encourage more recyclability and proper disposal. While Zenpack may use more than one material in a packaging design, we try to keep them separate and glue-free so that each piece can go in the right waste stream.

And lastly, if you’re interested, all the way at the bottom, we list the best packaging materials for shipping. Since we’re a full service packaging company these days, covering logistics too, it only makes sense to include that as well.

So below are the most common types of packaging materials, and some materials that may be more widely used by next year.

Wood Fiber-based Materials

Paper

Paper is one of the best packaging materials for shipping items. Whether you’re using kraft paper or cardboard—which is just thick, multi-layered paper—paper will protect your products and get them anywhere you need them to go.

Besides shipping purposes, paper is one of the most popular packaging materials, and is our favorite to work with at Zenpack. It’s versatile, renewable, recyclable, and toxic-free compostable—depending on the type of ink used.

One thing to keep in mind about paper, though, is that it comes from trees—at least the majority, currently. Tree-free pulps and fibers such as hemp, bamboo, and miscanthus at industrial scale are not too far off, but for the moment, trees are the main source of paper. And there are environmentally-friendly ways to harvest trees, and not-at-all green ways.

Zenpack uses FSC certified paper in its packaging, which is the gold standard of sustainably-sourced paper. Only 17% of the world’s production forests are FSC certified. What this means is A) there’s a limited supply. B) Some forest management companies will try to falsify certifications. Zenpack checks its sources thoroughly to ensure that all the paper used comes from confirmed FSC certified forests, and does not contribute to deforestation.

Some general pros and cons of paper are listed below, before getting into the specifics of the different types of paper packaging.

Pros

- Recyclable

- Renewable

- Biodegradable and compostable, depending on inks used

- Versatile

- Strong

- Protective

- Lightweight

- Low cost

- Excellent printability

- Aesthetically pleasing

- Available in many variations

Cons

- Not water resistant, unless coatings are used. Coatings used to make paper products water and/or grease resistant are often made with PFAS*. If looking for sustainable waterproofing coatings, look for paper packaging products that can be sold in California, New York, and Washington, as those states have bans in place on PFAS used for packaging food products. For cardboard boxes, moisture can decrease strength and protectiveness. *PFAS is a family of chemicals known as “forever chemicals.” The most commonly known one in this family is Teflon. These chemicals are used everywhere, from pots and pans to Gore-Tex and most grease resistant food packaging. They are known to cause cancer, reduce fertility rates, and are a major contributor to biodiversity loss.

- Generally not as durable as plastic, although this is dependent on use case.

- If not using sustainably sourced paper, it contributes to deforestation.

Kraft Paper

Kraft paper is thin paper often used in packaging. When unbleached, it comes in a natural light brown color. It’s strong, protective, and offers some moisture resistance. You’ve seen it used as brown grocery bags, as flour and sugar bags, and crumpled up as padding in Amazon boxes (known as void fill in packaging lingo). It’s puncture resistant and smooth, and in every Zenpack case study where you see paper, kraft is what’s used.

Paperboard

Paperboard is one of the most commonly used packaging materials at Zenpack and around the world. If you look through the Zenpack case studies, many examples of intricately designed boxes, folded structures and protection, and elegant printing quality and unboxing experiences were created with paperboard. It helps create projects that win awards.

One example of beautiful sustainable paperboard packaging with vibrant design is Zenpack’s solution for Etain, a medical and recreational cannabis company in New York. Bright colors made from soy-based dyes make the packaging stand out while also protecting glass jars and bottles. SBS paperboard is used for the fold flat boxes with the “tuck top.”

You can find paperboard in many retail products where the box folds, such as cereal and cosmetics.

Rigid Boxes

Rigid boxes are another type of paper-based packaging—but obviously much thicker and sturdier. The Apple iPhone box is a good example, as well as the box for the vape cartridges in the Etain example. These are durable, water resistant, and great for retail and display. They hold up.

Corrugated Cardboard

This is your classic cardboard box. If unbleached and made without synthetic dyes, it is completely compostable. In fact, it’s often used in composts to encourage organism growth. It can even be turned into seedling planters that can be put right into the ground. It can also be recycled up to 25 times.

Corrugated cardboard is one of the most versatile packaging materials there is. Its strength to weight ratio allows for easy shipping, it is abundant and inexpensive, and can be repurposed once its primary use is done.

Corrugated cardboard and paperboard are also finding uses as honeycomb padding and inserts to replace styrofoam. These protective pieces have shown to work excellently when used for glass and other items.

And while corrugated cardboard is often looked at as a shipping option for outer boxes, or as protection above, it can also be used for award winning designs, such as in the case of Brooklyn Robot Foundry.

Molded Pulp

Zenpack is turning to molded pulp with more and more projects, and while this is paper, it’s also not entirely made from trees. Tree-free fiber for the win.

Using the Drinkworks project as an example, we replaced plastic inserts with molded pulp made from a combination of tree fiber, sugarcane, bamboo, and recycled paper. This is a rather exciting area of packaging, as more and more non-tree fibers are starting to be utilized. Why does that matter? Trees take a while to grow—if a minimum of 12 years counts as “a while.” Leaving trees in the ground leaves their sequestered carbon stored there, too. And while using FSC certified paper sources is great, the cycle of cutting down trees and planting new ones isn’t as climate negative as simply leaving them alone in the first place—mature trees capture far more CO2 per year compared to saplings.

So when we have a chance to use non-tree fibers—which is often a waste product such as leftover fiber after sugarcane extraction—they pounce on the opportunity. Molded pulp has the same customizability as their plastic counterparts. They can be configured in any way to protect a product, and they can be dyed any color. (However, wastewater from dye baths is quite toxic, so Zenpack tries to discourage customers from going this route.)

Molded pulp, without synthetic coatings or dyes, is completely compostable. It is the sustainable way forward.

Wood

Wood is often used in both primary packaging—what touches the product—and as tertiary packaging, such as wood crates and pallets. Wood is both an elegant, luxurious packaging option, and sustainable to boot. As a natural resource, it’s renewable and the growing of trees and other woody plants is carbon negative (although the same can’t necessarily be said for manufacturing processes, as there are obviously many factors and you have to look at each process, including Scopes 1, 2, & 3* for each supply chain.)

*Scopes 1, 2, & 3 are the three degrees of emissions used to run a business. Scope 1 refers to direct emissions, such as those created by manufacturing a product. Scope 2 refers to indirect emissions from electricity purchasing. Scope 3 is the hardest to track, and refers to indirect emissions across an entire value chain, both upstream and downstream. This includes, but is not limited to, emissions from suppliers and harvesting raw materials, customer usage, and end-of-life of a product.

Below are pros and cons of using wood in packaging as a general guideline.

Pros

- Renewable

- Carbon negative

- Biodegradable and compostable, depending on treatments and coatings used

- Elegant and beautiful

- Strong

- Durable

- Long-lasting

Cons

- Heavy (raising transportation costs)

- Can be more expensive, depending on type of wood.

- Harvesting can lead to deforestation if not managed properly.

Bamboo

Ah, bamboo, what a material. It should be noted first off that bamboo isn’t a tree—it’s a grass. But it produces woody material that competes with hardwood for many uses. Tomayto, tamahto.

Anyway, bamboo is the fastest growing plant on earth. So when we talk about renewable materials, it’s kind of the cream of the crop as far as speed goes. Its pros and cons are the same as above.

Cork

Cork is the bark of cork oak trees. It primarily comes from the Iberian Peninsula (Portugal and Spain) and is completely renewable. What’s cool about cork is that harvesting it doesn’t involve cutting down trees—in fact you’d go to jail if you cut down a cork oak in Portugal. Cork is harvested every nine years, and then the bark is allowed to grow back so it can be harvested again—completely renewable.

Although it’s not a hardwood, it’s included here because bark doesn’t need its own category—let’s be honest, this is the only one that would apply.

You’ve probably seen cork packaging in many items. Beauty industry leaders such as Lush use cork for travel cases and cork is also used for shipping products.

Pros

- Renewable, biodegradable, and compostable

- Recyclable

- Fire resistant

- Water resistant

- Toxic free

- Carbon negative

- Lightweight

- Anti-microbial

- Insulating

- Protective

Cons

- Limited supply

- Not suitable for all packaging applications

Plastic Materials

- Polystyrene (Styrofoam)

- PET (Polyethylene Terephthalate)

- Polypropylene

- Polyethylene

- Ocean Plastic & Ocean Bound Plastic

- Biodegradable/Compostable Plastic

Fossilized dinosaur bones, liquified then solidified. I mean plastic, we’re talking about plastic here. Right, right, riiiiiight.

There are many different types of packaging materials that come from plastics, and many types of plastic. Each one is listed by its technical name, followed by its common name, if it has one. For the most part, an easy way to identify plastic materials when the technical name is used, is if the material starts with “poly” or the acronym starts with P.

Here are the pros and cons for plastic packaging in general, with specifics listed for each subcategory.

Pros

- Lightweight

- Strong

- Inexpensive

- Water resistant/waterproof

- Moisture barrier

- Can be flexible or rigid

- Moldable

- Can be transparent

Cons

- Made from fossil fuels

- Creates GHGs when oil and gas are drilled and fracked.

- Breaks down into microplastics, which are ingested by every living organism. At this point they’ve been found in brains, semen, and breast milk, on newly formed beaches and at the top of Mt. Everest.

- Degradation timeline can be hundreds of years.

- Leaches toxic chemicals when they’re landfilled.

- Pollutes the air when they’re incinerated.

- Limited recyclability (9% worldwide recycling rate)

- Recycling causes degradation and loses quality. Eventually (after about 5 times) the plastic will have to be removed from circulation.

- When you use plastic, you’re supporting an industry that’s spent 70 years manipulating the science of how environmentally harmful their product is.

- Chemical additives, such as BPA and PFAS, are known to cause cancer.

Polystyrene (Styrofoam)

This is your foams. Foam inserts, packing peanuts, etc. Polystyrene is one of the more ubiquitous packaging materials. It’s lightweight, protective, and shock absorbent. And for anyone who’s had to take their garbage out on a windy day, a headache, especially packing peanuts.

Polystyrene has been used for packaging for decades. It works. But the world is also dealing with the pollution that it causes. This is why Zenpack has been working hard on molded pulp trays—to eliminate styrofoam usage. Below are some styrofoam-specific pros and cons (everything listed above also applies).

Pros

- Insulating (good for shipping hot or cold items)

- Protective and shock absorbent

- Ridiculously inexpensive

Cons

- Heating it can leach hazardous chemicals into food

- Breaks down very quickly, scattering small pieces throughout the environment. Polystyrene is also the type of plastic tested when scientists discovered that microplastics can cross the blood-brain barrier.

- Extremely difficult to recycle

PET (Polyethylene Terephthalate)

Another highly common plastic material for packaging. PET is often used in drink bottles, shampoos, etc. As a textile, we know PET as polyester. Recycled PET (rPET) can be made into both packaging pieces and thread for textiles.

Zenpack has worked with rPET on some projects. While this isn’t ideal, it’s worth noting a couple of points:

- Waterproof natural threads don’t exist at scale yet.

- Transparent compostable materials don’t exist at scale yet.

While the company would like to work with only sustainable materials—and they keep an eye on developments—there aren’t materials for every use case just yet.

Below are some PET pros and cons.

Pros

- Comes in both rigid and flexible forms

- Transparent

- The most widely recycled plastic

Cons

- As the most widely used plastic, it’s also the one most likely found on beaches and in oceans.

- As the most widely used plastic, it’s also the one most likely found on beaches and in oceans.

- Washing polyester—recycled and virgin—also releases microfibers into water systems. Just as other microplastics mentioned above, these fibers are consumed by all living organisms. These minuscule fibers up to 0.5mm long have been shown to stunt the growth of mussels, as just one example.

Polypropylene

This is another type of plastic often used in bottles, caps, reusable tote bags, etc. Like PET, it’s used in many different types of packaging, available in both rigid and flexible forms. Because it’s so durable, it’s often used to make hinges for closable containers, able to withstand the back and forth of opening and closing. It is also a common type of plastic used to make poly bags for packaging, along with polyethylene.

Polyethylene

Polyethylene is your classic flexible plastic material. Like PP mentioned above, it’s used to make poly bags, and also many of your flexible plastic films, such as stretch wrap. A subcategory of PE is LDPE (low density polyethylene), which is used to make bubble wrap. If you ever see any of these acronyms, just know that they’re all plastic. PE and LDPE are virtually non-recyclable. Technically they are, but in practice and due to their low value, it doesn’t happen.

Ocean Plastic & Ocean Bound Plastic

You may have heard of them in some form or another, but truth be told, these terms are misleading. Ocean plastic is a marketing term that makes it sound like the plastic was fished straight from the ocean, and then either reused or recycled. The problem is that plastics fished from the ocean are too degraded to be recycled into new materials. Even when mixed with virgin plastic, the saltwater has a negative effect on the material, so it doesn’t perform well, and can’t be recycled.

Windex was accused of greenwashing a couple years ago for using the term ocean plastics, and has since switched to using “ocean bound plastic.” And in April 2023, Moo Yoghurt in Australia had a complaint brought against it for using…you guessed it, “ocean bound plastic.” The greenwashing complaint is currently under review by the Australian Competition and Consumer Commission (ACCC).

“Ocean bound plastic” basically refers to plastic picked up within 50 kilometers of coastlines, plastic that could possibly reach the ocean. But this is a little misleading, because there’s no way to confirm that plastic would reach the ocean, and because 60% of the world’s population lives within 50 km of coastlines, that’s where the majority of plastic would be used anyway.

Zenpack uses Repreve Our Ocean recycled polyester on some projects, which Repreve labels as ocean bound plastic. Yeah, it’s not a perfect material, but it is certified 100% recycled. And sometimes there’s a project that calls for plastic usage, or a customer requests it. In these cases, we ensure we aren’t using virgin materials when we don’t have to, and are constantly scouting for new materials to replace it—there’s a pretty good section below detailing emerging materials.

Biodegradable/Compostable Plastic

This is kind of an all-inclusive term that may or may not mean much, depending on the individual material. There are many bioplastics now, but some have varying amounts of refined fossil fuels in them, and some are made in a way that makes them industrially compostable, but not home compostable.

The difference is timeline and temperature. Industrial composting facilities reach higher temperatures and maintain them consistently compared to a backyard compost pit. The other issue is time. To be industrially compostable, an item needs to break down in about 9 weeks, whereas there is no timeline in your backyard—a tree branch is not considered industrially compostable because it takes too long.

Also, industrially compostable can be construed as greenwashing, depending on where an item is sold. If there’s no industrial composting facilities in an area, then the item will go to landfill, and the label isn’t accurate.

As for industrially compostable bioplastics, PLA is a very popular biobased one right now that is made from corn. But the term biobased can also be misleading, because it leaves open the door for additional chemicals. If this is all confusing to you, don’t worry, it’s confusing to most people. There is no simple answer to this group of bioplastics, except that when looking at one, ask as many questions as needed to find out what it’s made from and its worst-case end-of-life scenario.

And with President Biden announcing a goal in March 2023 that 90% of plastics should be made with biomaterials within the next 20 years, we’re going to start seeing a lot more of this. For more information on individual materials that can be turned into paper products or bioplastics, look at the Uncommon Materials section below.

Glass

Such a fine, fine, fine material, this is the historical option for most drink products, elegant or otherwise—although aluminum has been giving it a run for its money for 80 or so years. Glass is essentially sand that’s been melted down. It is infinitely recyclable. This means that unlike plastic, it doesn’t lose quality no matter how many times it’s remade.

Everyone thinks of glass as this fragile, heavy material that needs to be cradled. But as Zenpack Co-founder and Director of Design Leo Chao says, “Glass, surprisingly, is not as fragile as one might think.” And indeed, have you ever dropped a mason jar and were shocked to see it didn’t crack? This isn’t to say that glass can’t break, but it also doesn’t need to be buried under 3 layers of packing peanuts just to ship a jar.

Glass is a great primary packaging material, and if you need to protect it, honeycombed paper is one of the most effective and sustainable ways to do it.

Below are some pros and cons of using glass for packaging.

Pros

- Infinitely recyclable

- Reusable

- Aesthetically appealing

- Waterproof

- Sealable

- Chemical-free

Cons

- Heavy, which raises transportation costs

- Breakable

- High manufacturing emissions—these can be offset by reuse.

Metal

Zenpack doesn’t work with metal very much, but it’d be a disservice to this piece if something about it wasn’t included. Steel and aluminum are two widely used metals for packaging. Aluminum is infinitely recyclable, and steel is of such high value, that recyclability rates are above 90%. Although steel is not really used much in consumer products—save for tin cans used for food—shipping containers utilize it, and most products encounter it at some point in their journey. Metals create high manufacturing emissions but can be reused in some cases, and their recyclability reduces mining of virgin materials.

Glue

The type of glue used in packaging depends on the surface of the materials that are bonded together. Paper with paper will use one type of glue, metal with wood will use a different type.

According to Chao, there are three main types of glue used in packaging. The first two are both synthetic. One is white, and basically like Elmer’s glue. The other is yellow, strong, “smells bad,” and somewhat closer to an epoxy.

The third type is hide glue, made from melted down bones and fat from animals, along with glycerin from sugar cane, and water. It’s plastic-free and called jelly glue in China because of its appearance.

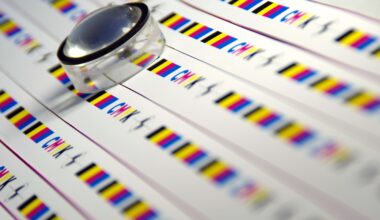

Ink

Most ink is not absorbed into the material, but instead sits on top, drying. It’s much like glue, states Chao. Both ink and glue need to adhere to the surface of the material you’re working with. There has to be some mutual stickiness. And when it comes to paper, coated vs. uncoated paper has a huge impact on what type of ink is used.

The two types of ink primarily used in packaging are synthetic, oil-based ink, and soy-based ink.

Synthetic inks have varying percentages of soy in them to create the right mixture of color and adhesion. And soy-based inks are not 100% natural—with a minimum of 11% synthetic materials in them to make them sticky enough for adhesion.

In fact, to be called “soy-based” just requires 6-40% soy-oil, depending on the type of ink.

There are also water-based inks—still containing synthetic materials—that are used mainly for corrugated cardboard. And UV inks (synthetic) that are cured using UV lights—very similar to UV nail polishes.

And lastly there’s a new type of ink that’s come out recently: algae ink. One company working with algae, Living Ink, claims that it’s completely synthetic-free. However, at the moment, algae ink only comes in black. It’ll be interesting to see how this develops…and algae seems like a good lead-in to the next section here.

Uncommon Packaging Materials

These are the fun ones, because this is where the future lies. These materials aren’t scaled for widespread use just yet—but they could be by next year. Who knows? This comes down to investments, manufacturing, and more R&D—there’s quite a bit of that last one going on though.

Mycelium

Mycelium is an interesting case. First off, it’s the roots of mushrooms. Mushrooms are the fruit, mycelium is the roots, basically. There are millions of dollars in mycelium research right now. And we’ve seen some limited use cases of it already, such as this shoe box made in a collaboration with Mr. Bailey, Adidas, and Magical Mushroom Company.

Mycelium is fast growing, moldable, and compostable when not coated with PE or PVC. It seems to have a wide range of uses from boxes to protective inserts, but for all the investments, we haven’t seen much of it in use yet. Maybe one day?

Seaweed

Brown seaweed is one of the fastest growing plants in the world. One adopter of plant seaweed, Notpla, just won the 2022 Earthshot prize for its completely biodegradable and toxic-free packaging. It will literally dissolve in water in 15 minutes. Holy crap how is that not cool?!

But it probably won’t work for a plastic bottle, or anything where it’s likely to get wet. If you want to see it in action, though, check out this watch case they made in collaboration with ID Genève.

Hemp

Yeah, 100% hemp paper already exists. What it needs is funding, and for the US federal government to stop testing a fibrous plant for THC. No one is smoking that nonsense. Ooh, it’s got 0.4% THC, whoop-dee-doo. (And that’s when the feds destroy the crop, because it’s over 0.3%.)

Miscanthus

Giant miscanthus, known as elephant grass, is a perennial plant native to China, Taiwan, and Japan. It’s currently grown in the US for use in biofuels, but a few companies in the UK and Europe are harnessing its abundance of fiber for packaging. Thermoformed molded food trays are the focus of one of these companies, and more items are on the horizon. With more investments, this could be a material widely used soon enough.

Chitin

Crustacean shells. It’s unknown how many people are studying this material for packaging, but one company has already released it for use. It’s a foam replacement (think styrofoam), originally developed to take the fossils out of surfboards.

Agriwaste

That’s shorthand for agricultural waste. This covers the stalks and other pieces of plant matter left out in fields after harvest. It also includes waste materials after food processing, such as spent barley from beer. And it includes wood chips and tree trimmings. Basically if it comes from a plant and no one has claimed it for use yet, it’s agriwaste.

So what can agriwaste be made into? Oh, only a completely compostable replacement for styrofoam. And all sorts of standard packaging components, such as inserts, boxes, and more. Agriwaste is the real deal. The research is there, the trials have taken place. By this time next year, these might be scaled and could be the best materials for packaging.

Shipping Materials

So while we’ve looked at some of the most common packaging materials, we should also look at which are the best types of packaging materials for shipping.

Keep things simple and natural. Wood pallets and crates, corrugated cardboard boxes, and if you need protective padding, paper. As we’ve shown above, paper and molded fiber are becoming the new bubble wrap, the new packing peanut, the new insert. With these three materials, you can ship anything safely. And if you need someone to handle that, well, you know, we could probably help.

If you want to know more about Zenpack’s services

Let our packaging consultants help you turn your idea into reality.