While ink is a much-talked-about topic these days, with everyone using soy ink and such, packaging glues are even more invisible—but obviously just as important. Just like if a baseball player slips on the warning track and announcers start questioning whether he was wearing cleats or spikes. Out of mind until it matters.

A well-designed label won’t stay on the bottle without the right glue. A new phone falling out of a box that won’t stay together isn’t a new phone anymore, dinged up and cracked screen.

Packaging glues—adhesives (dictionaries and adhesive companies alike can’t seem to agree on the differences between glues and epoxies, so while these are all adhesives, we’ll just use the colloquial “glue”)—probably don’t take up a lot of your mental energy. But if you suddenly have questions about them because someone brought it to your attention, that’s what we’re trying to sort out here.

What are packaging glues made from? How do they affect your sustainability goals, such as recycling or composting? What plastic-free solutions are there—or going to be available soon? Let’s find out.

Packaging Glue and the Substrate

The glue is not the first decision—it’s the substrate, what you’re trying to glue together. Different glues work better with different substrates, wood with metal, plastic with plastic, paper with plastic, paper with paper—you get the idea.

“As you can imagine,” said Leo Chao, Creative Director at Zenpack, “uncoated paper absorbs moisture. Some glue is not great for that because it absorbs a lot of water, moisture, really quickly, and it dries really fast. So a glue that dries too fast might not be suitable for uncoated paper.

“Generally speaking, uncoated paper doesn’t necessarily need stronger glue, but it does need to have glue with a lower moisture level.”

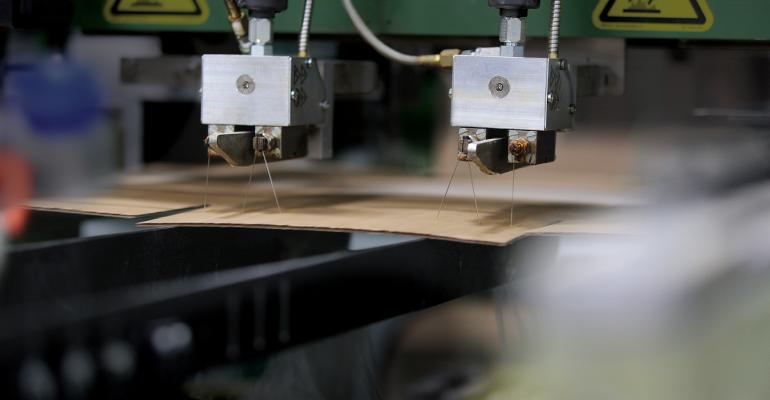

If glue dries too quickly, then there might not be enough time to bond your two substrates together in a manufacturing line. Therefore, the speed of your line and the drying time of your glue need to work in sync.

Another aspect that needs to be taken into account is not just the substrate, but the coating on it. Let’s say you’re gluing paper to paper, but there’s a film on one of them. “If the substrate has a film,” Chao said, “that now becomes a plastic surface. Again, use different glues.”

When you know the substrate, you can narrow down the glue to use.

But shouldn’t you always strive for an environmentally friendly glue? Yeah, that’s ideal. However, if you’re working with plastic substrates, a natural glue isn’t going to make much of a difference.

It should also be noted that the first job of packaging is to protect the product. If the packaging isn’t holding together because the wrong glue was used, then damaged, unsalable products are much more polluting than a synthetic glue.

The hope of many of us in packaging and the developers working on glues is that we can have both a natural glue and one that works with different substrates to create strong protection.

So then, what types of glue do we work with in packaging?

Types of Packaging Glue

Glues—adhesives—are often referred to as what they’re made from or how they work. We’ll go with the first one, what they’re made from. This determines a glue’s end-of-life scenario and how much it can affect recycling.

Chao also mentioned that when it comes to choosing a glue, how the packaging will be used is another determining factor. “Things get complicated when the requirements for the packaging call for extreme temperature change or moisture change. The glue needs to withstand environmental effects.”

So with that in mind, here are the common adhesives currently used in the packaging industry, starting with the three Zenpack uses the most.

For a quick reference guide, download our comparison chart here:

White Glue

This is basically your standard Elmer’s-type glue that you played around with in elementary school and put all over your hands to dry so you could peel it off.

It’s water-based and water-soluble, and made from PVA (polyvinyl acetate—not to be confused with polyvinyl alcohol, which is a synthetic polymer used in plastic applications), which is a synthetic material. This is one of the most common glues Zenpack and the entire industry uses. It works exceptionally well for paper substrates, including paperboard and corrugated.

Chloroprene Adhesive

Chao describes this glue as super strong with a horrible smell. This rubber adhesive is made from neoprene, magnesium oxide, anti-aging agent, antioxidant, and filler.

It’s a synthetic adhesive, and while Chao doesn’t like to use it in many cases, it has its uses, such as for plastic to plastic or film-coated paper. It is also resistant to water and oil—for packaging that requires that sort of thing.

Hide Glue

Also known as jelly glue in China because of its appearance, this is your traditional idea of glue. It’s made from melted down animal hides and bones, and combined with glycerin and water. Another common name for this glue is gelatin glue.

Chao says it’s not as strong as chloroprene and white glue, but Zenpack is moving towards using it whenever possible, as it’s a naturally derived material, nontoxic, biodegradable, and the only non-synthetic widely available. It’s often found in bookbindings and rigid boxes.

Hot Melt Glue

This is basically the type of glue you’d find in a glue gun for a home project. Except on an industrial scale. It’s a synthetic glue typically often made from EVA with fossil-fuel inputs.

Hot melt glue is quite strong, and is used in packaging for plastics and paper, foams, metals, corrugated cardboard, and labeling bottles.

Other Types of Glues and Adhesives

As with inks, there are many types of glue. People can do some fancy stuff with fossil fuel-based chemicals—just look at the estimated 5,000 to 15,000 types of PFAS (forever chemicals, popular brand name: Teflon), which are derived from coal, oil, and gas.

We’ve listed some of the most common ones, and the ones we use at Zenpack. But other glues that are found in packaging—and are all synthetic—include:

- Polyurethane

- Acrylic

- UV curable adhesives

- Epoxies, which are reactive chemicals involving the mixing of a resin and hardener.

Then there are also pressure-sensitive adhesives (PSA), which include stickers and stamps. These are non-recyclable—which we’ll get into in a moment—and are usually made from acrylic, rubber (more often synthetic than natural), or silicone (which is more expensive).

Advancements in Glue—Plastic Free Solutions Coming to Market

There is some work going on to create plastic free glues that are natural and nontoxic.

- Starch from corn or potatoes is becoming a more common option for fossil fuel-free glue. IKEA has even started using it in its manufacturing. They can also be found in some PSAs.

- Staying with corn, researchers have combined a protein found in corn with tannic acid to create an adhesive that grows stronger in water. The team says that gallons can be made within hours, anywhere on the planet. And with further formulation developments, the adhesive could be used for “construction, manufacturing, biomedical, dental, food and cosmetic[s].”

- Tree resin has been used for thousands of years to make adhesives—dating back to Egyptian times—and it’s making a comeback now. Scientists are working with poplar trees to make a new type of tape. And on the fashion side—hopefully this jumps to packaging sometime soon—conifer tree resin and natural latex have both been used recently as an adhesive for footwear.

Recycling Glues

Just like ink, recycling glue isn’t really a thing. It more often than not doesn’t limit recycling, but the glue itself is not recycled.

Take paper, for instance. The first step in recycling paper is to de-ink it. This involves submerging the paper in water and creating a froth, where the ink collects, while the pulp sinks to the bottom. And just as with ink, this is where glue ends up, to be skimmed or screened off.

But after the froth is collected, what happens to it? Where does it go? While many people are asking these questions in regards to ink—probably because it’s bright and visible—the same question applies to glue. It’s discarded in some way—which way depends on the recycling facility.

(While it may seem trivial, creating a waste-free world includes all these little things that add up.

A good example of little things adding up is oxybenzone, an ingredient often found in sunscreens and that’s been eliminated recently in coral-safe sunscreens. From the New York Times: “A single drop in 4.3 million gallons of water — about six and a half Olympic-size swimming pools — is enough to be deadly.”

While glues aren’t that toxic—waste, pollution, run-off, and landfilling are all things we want to avoid.)

So while glue isn’t recycled itself, it more often than not doesn’t affect recycling.

However, stickers and stamps are usually chopped up along with the rest of the paper that’s recycled. The adhesive that’s still on them can create what’s known as “stickies” during recycling and reprocessing the pulp.

Stickies are exactly what they sound like: clumps of pulp that stick together and refuse to be flattened out to make new paper. For this reason, recyclers will often reject paper that has too many stickers or stamps on them.

Compostable Glues

Compostable glues can obviously make a difference in the overall sustainability of your packaging. Using corrugated as an example, while it is recyclable and that is the best end-of-life for it as recycling keeps the pulp in circulation, uncoated cardboard is considered compostable, and there may be times when recycling is unavailable.

Using compostable glue with seaweed packaging—which doesn’t have a recycling waste stream yet but is compostable—will ensure that the entire packaging will degrade naturally and free from toxic chemicals.

But what glues are compostable? This is tricky. It’s hard to say for certain unless there’s certification to back up the claim, which is individually applied.

For industrially compostable glues certified in the US, look for ASTM D6868, which is the industrial composting certification for plastic and polymer coatings and additives on paper and other substrates. As for home compostable certification, none currently exists in the US.

Now, having said that, jelly glues should be compostable because they’re made solely from natural ingredients that can decompose without toxic residues. But again, nothing can be said for certain without seeing the MSDS or composting certification for the glue you want to use.

How About Some Packaging To Go With That Glue?

Most people don’t really look at glue, but they notice it when it doesn’t work. If you’re a baseball fan, it’s just like umpires. You don’t know the names of the good ones, but everyone knows Angel Hernandez.

So if you need some packaging, and you want glue that works for the purpose of your packaging, and a company that works to make packaging as sustainably as possible—including the glue—talk to Zenpack. You know, we’ll do what we can.

If you want to know more about Zenpack’s services

Let our packaging consultants help you turn your idea into reality.