It’s that time of year again: prediction season. Some of these are actual trends, and they’ll fall out of favor soon enough. And some are actually the next big thing, here to stick around.

Together with Zenpack Creative Director Leo Chao, we came up with what’s in store for 2024, packaging trends-wise.

1. 2024 Will See an Explosion of More Sustainable Practices in Packaging

In 2023 we saw ventures into adopting more sustainable packaging practices, from McDonald’s in France switching to reusable tableware, to many brands starting to introduce paper packaging. That was the start.

Although biomaterials are often discussed in this blog, most of them currently under development won’t hit the public sphere until 2025. But 2024 will see many new initiatives take off, from more examples of plastic free packaging, to global brands eliminating PFAS use.

And while BPA has already gained widespread attention for years now (if you ever buy new Tupperware or a reusable bottle, you’ve seen the BPA-free sticker), other bisphenols will come under increased scrutiny. Chemical additives and pollution will receive much more attention, and while governments may still be slow to limit or ban them, public pressure will force companies and brands to phase these chemicals out.

Waste will also decrease, with more focus on design and simply using less materials.

Now, a lot of this is also related to greenwashing. With greenwashing regulations tightening in the US, EU, and UK, brands can no longer say “good for the environment” without proof backing up those claims. Many brands will try, and they’ll be called out and fined. By the end of 2024, not only will packaging be more widely made with more sustainable materials and fewer chemical additives, but what’s printed on the packaging will be clearer for regular consumers to understand. (Tl;dr “compostable” will mean compostable.)

We’ve separated a few practices below that we think will boom in 2024, but Chao says that sustainability won’t just be about reducing our impact on the environment, but also being “considerate of policy, politics, regional conflicts, and disasters.”

Seaweed Becomes Household

Sure, I just said that 2025 would be the year of biomaterials, but one is coming a bit early in 2024. Maybe it’s because Notpla won the 2022 Earthshot Prize and spent all of 2023 promoting it. Maybe it’s because I’ve spent the last year hearing about seaweed packaging nonstop. Maybe it’s just because Notpla was used at a Portland Trail Blazers game in December 2023. England>>>Portland. That kind of global reach has potential. Anyway, who knows? And they’re not the only ones doing cool stuff, as you can see in the photo above that Sway in the US is making its own (seaweed) waves.

But while it’s well known what seaweed can do in the biomaterials space, and it’s gotten a lot of press recently for packaging, it isn’t well known among regular consumers—yet. That will change in 2024.

Obviously not every brand is going to be switching to seaweed packaging—nor should they; it currently has its limitations like everything else. But enough articles and social media videos will come out between now and the end of 2024 that seaweed will be the hot new thing in packaging.

Refillable Packaging Takes a Significant Jump

Refillable packaging isn’t new, but it’s also not mainstream yet. Brands introduce it, try it for a bit, don’t see results (perhaps because they don’t publicize it well), and then drop it. But in places where it works, it works. And it’s well-publicized.

It’s also one of the most impactful ways brands can lower waste, pollution, and greenhouse gas emissions. While more brands were starting to introduce refillable packaging towards the end of 2023—such as Palmolive—there has been little data to gauge customer interest. And there has been obvious speculation about how long these programs will last and if they work.

I don’t know how many of these will last, but I will state that many big brands will try out refillable packaging in 2024. We’ve already seen many DTC brands successfully implement refillable packaging for hair and skincare, liquid soaps, deodorant, and more. Chao agrees: Refillable is flying in, and the big brands are jumping on board in 2024.

Reusable Packaging Gains Momentum

Obviously refillable packaging is reusable, so why’s there a separate section here? Well, refillable packaging typically is applied to consumer-facing, consumable products like those mentioned above.

But I also think the non-consumable market like electronics and appliances will also start to take advantage of reusing their packaging, saving money and resources.

This trend has already started, with fashion brands encouraging returns in the same packaging and footwear brands using the primary box as the shipping vessel, too. Items that are more B2B in nature, like machinery parts, will also start to use reusable packaging.

And while we may not hear about that as much—is it really a trend if it’s not well-publicized?—companies everywhere will start to see the cost-savings of making packaging that only needs to be made once.

2. Materials For Differentiation, Not Just For Sustainability

Chao says that more materials will be used in packaging—not just for sustainability, but “the desire to be different. This used to be done with graphic design and special treatments, but I think brands will move away from that to more tactile, material-based strategies to enhance differentiation.”

In a world of smooth touchscreens, this feels right. But hopefully we don’t see many examples of Franken-packaging, with multiple materials and a thin layer of something “sustainable” on top for the finger feel.

3. Interactive Packaging

This isn’t your grandfather’s interactive packaging—or packaging from even a year ago.

“2024 will be the year where connected packaging becomes interactive packaging,” Chao said. “The QR code on the box that leads you to a video or site will not be enough. With AR/VR hardware advancements, packaging will become more interactive, personalized, and given more marketing value.”

4. Packaging at Extreme Ends of the Spectrum

Packaging, like so many things these days, is segmented. And knowing your customer is key to whether something will work or not. Which is probably why the extremes are getting so much work now—there’s room to segment.

Polarized Packaging

Chao says that the overall feel of packaging will take on one of three extremes in 2024:

- “Packaging that’s like the product: useful, replacing single-use.”

- Minimal to the point of eliminating it altogether, “as things like a mail shipper or bag need to be extremely simple to avoid the feeling of over packaging.”

- “Packaging that’s so nice you want to keep it. As a response to #2, people will look for packaging that is extremely premium and they will want to keep it forever. Brands need to find a way to give new meanings to their packaging, either through aesthetics or functionality.”

Nostalgia, or “Retro Everything”

Two time periods that are already starting to take off again are the 90s and the 50s, with brands eating up the feel of bygone eras. Chao says this will only get more pronounced, with brands bringing back first-generation logos, colors, art directions, etc.

“The search for the golden era is still strong,” he said. “When the future is uncertain, we find comfort in the old, familiar, family, and pastime.”

Childlike Graphics

Chao says that scribbled, childlike graphics will become more prominent in visual design.

“There are a few brands that intentionally make the graphics on the packaging so crude, it almost feels like they don’t have money or want to spend on packaging (to emphasize their product is so pure that they don’t care about packaging). This might also be a response to the super-refined AI-generated graphics.”

He says that this can easily go bad quickly, and customers can turn on brands that use this approach indiscriminately. “The winners will be the ones who use this style with carefully designed layout, proportion, and symbols.”

Very Loud Fonts

While Apple’s minimalism will always be in vogue, at least for some people and as long as it’s one of the top consumer companies in the world, that’s not a trend anymore. Instead, amidst all the noise of 2024, the trend is who can yell the loudest.

“There seems to be a race to who can produce the biggest and boldest fonts on the box,” Chao said. “It works well with some product categories, but it fails when you neglect your user group.”

2024 and Beyond

Some of these predictions are safe, some might be a little out there, but there’s a high likelihood they’ll all happen.

And even if they don’t, Zenpack will continue to put out good work. Waste-reducing work. And we’ll always be looking for the next thing. If you want to be a part of this work, here you go. Packaging is looking up. Or down. Or whichever way uses less of it.

Want more trends? Check out last year’s post below.

Each year, we look to Leo for the latest packaging trends. While we usually take his notes as a guide for further research, we have a hunch his packaging prescience will continue (just like last year). So this time around: no revisions, no editing, just Leo.

1. Using the Entire Canvas

The ultra-minimal aesthetic that started mostly by brands who wanted to be more “Apple”, I think has officially ended. Why? The rise of direct-to-consumer brands during the pandemic has created too many look-alike brands that use enlarged sans serifs. As things started coming back to retail, people wanted to be stimulated with more colors, contrast, and curves, which is partly why the Y2K trend is making a comeback.

We will still see minimal design aesthetics, but I think the wave is going towards to a louder visual. I hope we’ll see more refined work that embraces real minimalism, not merely copying the Apple look. On the other end, I think we’re going to see some noisy and overly decorated designs that hopefully will quickly find their way to becoming something new. As providers of top-quality packaging design services, we are always on the lookout for emerging trends and ideas that can help our clients stand out from the crowd.

2. Sustainable Is the New Luxury

This may feel like old news, but it’s not cool to be wasteful. That’s been one of the recurring packaging trends for years now, but the luxury brands are now embracing the corrugated look. Kraft is the new black, so to speak. I think this is one of those packaging trends we’re going to see developing over the next few years. I think brands are rushing to find the next recycled ocean plastic material. While I think brands’ intentions aren’t purely green, the drive can help new startups gravitate towards more sustainable material. I predict an explosion of all kinds of bio-materials coming to the scene.

3. Omni-channel Packaging Is Back

A trend that might be less noticeable is omni-channel packaging. This topic was on the rise pre-pandemic, and obviously abruptly ended. DTC brands are realizing they can’t be online only, and most of the retail-only brands that survived likely found their way into online channels. As their growth depends on how well they can adapt to the other channels previously absent, their packaging will need to merge, rebrand, and reinvent to perform well both online and offline.

4. Everything E-commerce

Recently I’ve been surprised, and impressed, by some of the products making it to e-commerce. Zenpack has received some strange requests in the past, but as consumers become more and more accustomed to e-commerce, these requests don’t seem so strange.

For example, with the rise of e-commerce DNA testing kits, medical and wellness brands are rolling out all kinds of services that were previously restricted to the doctor’s office. We worked with True Marker, a home medical testing company, to develop a packaging system to send a variety of easy-to-administer tests to patients across the country.

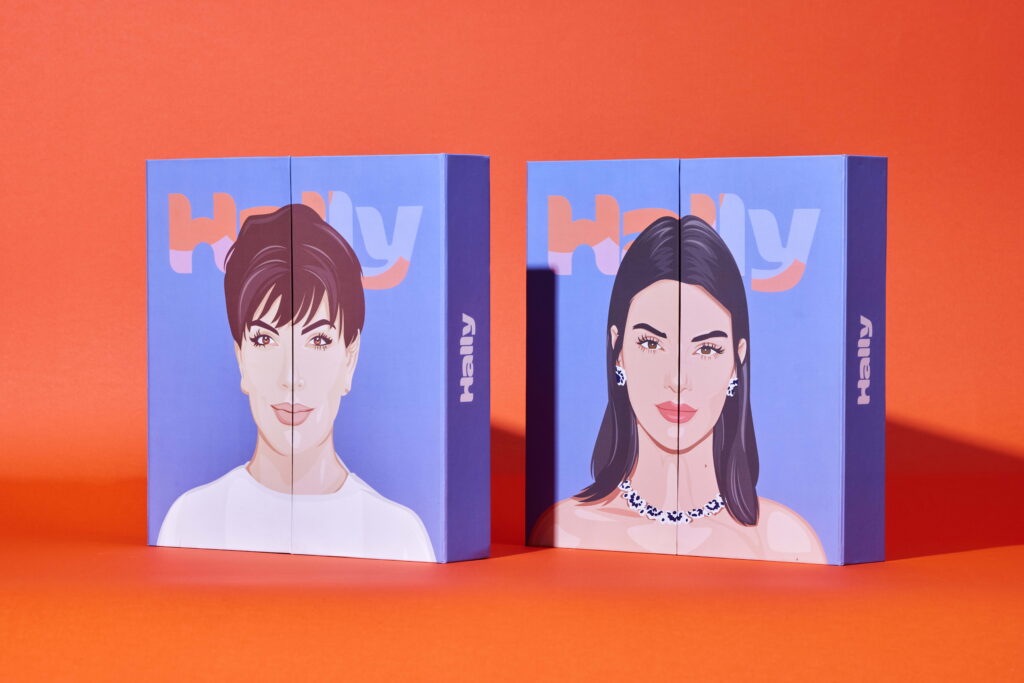

5. Custom But Not Costly

Most people think that small-run influencer packaging costs thousands of dollars per unit. The truth is that influencer marketing campaigns can be quite affordable, especially considering the potential reach. From big brands to startups, companies are devoting modest budgets to custom packaging runs as part of the overall strategy.

Last year, the renowned fashion brand Diane Von Furstenberg approached Zenpack to create a one-of-a-kind packaging design for the reissue of their iconic 1973 wrap dress. Only 25 packaging sets were produced, but we leveraged structure and materials to keep costs low. Crafted entirely from paper, the book-style box can lay flat for easy assembly and cost-efficient shipping.

Want to see how packaging trends have evolved? Check out our 2022 trends below.

We examined our favorite projects from 2021, including a few of our own and a selection from all over the packaging world.

Projects range from cosmetics and skincare to at-home education and food. When we predict packaging trends, we tend to let our optimism take over. One theme continues to run through every one of these trends: design with a purpose. Whether that’s sustainable materials or intelligent structural engineering, we noticed the packaging world really stepping up when it comes to multifaceted design thinking.

- Sustainable Design

- The Evolution of E-commerce

- Every Package Tells a Story

- Paperboard Over Plastic

- Inclusive Packaging Design

- Say Goodbye to Single-Use

- Minimal Packaging for Maximum Protection

Sustainable Design

It seems that every year, industry experts list sustainable design as one of the next packaging trends. At a certain point, the trend becomes the standard. Unfortunately, we’re still in a long-term relationship with plastic that doesn’t look to be ending anytime soon. It’s complicated. But year after year, designers continue to come up with innovative sustainable packaging solutions that give us hope.

There’s no denying that plastic packaging has in many ways improved our lives. We use it to preserve food, protect people from harmful substances, and deliver life-saving medication. For example, the ubiquitous orange and white pill bottle. It’s hard to imagine this everyday object being made from some material other than plastic. But we use 5 billion bottles per year (that’s just the United States!), and most of them don’t get recycled. If the packaging helps the user but harms our planet, how effective is the overall design?

A team of designers decided to answer this question with the first ever Prescription Paper Pill Bottle. Saatchi & Saatchi Wellness and Tikkan Olam Makers collaborated to create a bottle and lid made from 100% compostable and biodegradable paper. The design not only meets FDA regulations for child resistance, labeling, water, and light, but the firm has also released their work as a free, open-source design toolkit for pharmacies to use all over the world.

In 2022, design studios, packaging manufacturers, and hopefully brands will continue the slow march to sustainability. They must accept the difficult challenges. They must rethink our old ways to transform previously unsustainable products into quantifiable eco-friendly alternatives. Learn more about Zenpack’s sustainable packaging design services.

The Evolution of E-commerce

This may feel like old news, but e-commerce continues to evolve, forcing businesses to keep up. In the wake of the COVID-19 pandemic, constrained supply chains and increased demand cause major problems for business of every size. As customers increasingly rely on e-commerce, brands are realizing the power of packaging.

Online shopping increased by about 80% during the pandemic. Companies quickly realized that without the right e-commerce strategy, returns poured in and their brand suffered. Maybe the product was damaged in transit, or perhaps it didn’t live up to the image presented online. Essentially, retailers underestimated the full experience. It doesn’t end when the customer clicks “Complete Order”; instead, it extends all the way to the customer’s home where they get their first interaction with the product.

As brands realize the that the physical experience doesn’t always—and sometimes can’t—take place at the mall, they will use the package as a canvas to tell their brand story. Even a raw cardboard box can serve as the backdrop for layers of rich storytelling. Brand ambassadors, also known as influencers, can help to be your narrators, reaching a whole new online audience. In the end, the unboxing experience lights the way, from the shipper messaging all the way to the squeeze of a bottle dropper. And, if this is something your brand is investing on, we also specialized in influencer packaging.

Every Package Tells a Story

All sides of the package are printable surfaces. Yes, that includes the inside, under the lid, even the flaps. And there’s a reason to take advantage of modern printing capabilities (other than it’s fun): connecting with consumers through narrative. Just like writers crafting a compelling story, designers pour untold hours and energy into product and packaging design. Through packaging, brands can use materials and the product or service itself as a medium to share their company values and mission. The customer can even become a character in the story.

Brooklyn Robot Foundry took this approach to another level with their recent rebrand. As the name suggests, Brooklyn Robot Foundry started in Brooklyn where they teach kids basic STEAM concepts through hands-on robot-building. They were first an after-school and weekend program, but once the pandemic hit, they shifted to an online platform. Using kits sent from Brooklyn, students learn to build from teachers over Zoom. This new model required better packaging to hold the parts, tools, and activities required for each class.

The new packages are bright orange boxes of fun that tell the story of the Brooklyn Robot Foundry family of robots. Each side of the box tells a chapter in the story, and each layer provides a new activity or directions. The robots are working together—outside on the Brooklyn streets and inside the Foundry—to build a sign with the BRF tagline, “Building fun together.” When it’s time to start class, kids can transform the box into a laptop stand.

Paperboard Over Plastic

When you’re in the grocery store, do you ever wonder why so many fruits and vegetables are packaged in plastic? Tomatoes in clamshells, cucumbers glistening with plastic wrap, apples in a clear plastic bag. The short answer: Plastic is the perfect combination effective and cheap. The more complicated answer: The petroleum and plastics industry has an endless supply of money for marketing and lobbyists to ensure plastic remains king.

We often forget about the everyday packaging of produce, snacks, and beverages, but these categories comprise a large part of the market. As America’s plastic recycling problem comes to light, many produce suppliers are turning to paperboard and cardboard containers. These materials are clearly more sustainable, and they offer more space to print branding and nutritional information. According to the North American Paperboard Packaging Council, they predict that both large manufacturers and small family farms will begin choosing paper-based containers over plastic.

Inclusive Packaging Design

Throughout the past few years, major brands have been focusing long overdue research and energy on inclusive packaging design. Universal design considers all genders and abilities, with the goal of achieving accessibility for all. In the cannabis industry, the law requires CBD and THC products are sealed in child-resistant packaging. These mechanisms protect children, but they cannot be too difficult for people living with disabilities or the elderly who also need to access the products inside. Zenpack has been focused on creating awesome cannabis packaging designs.

In spring 2021, Unilever released “the world’s first deodorant designed for people with disabilities.” Degree Inclusive is an adaptive deodorant intended for one-handed usage. Designed for customers with limited sight or mobility, there’s a magnetic closure and modified grip. The product will officially launch soon after Degree incorporates usability study feedback.

When it comes to inclusiveness, even something as simple as changing packaging color can go a long way. Cosmetics and skincare companies are ditching outdated gender stereotypes, opting for more neutral colors. Since their products are intended for more than just women, Fenty Skin uses earthy green containers rather than pink. This year, expect this trend to continue as brands attempt to reach a wider audience with more inclusive colors, textures, and packaging designs.

Say Goodbye to Single-Use

In response to consumer demands, retail and e-commerce brands are figuring out ways to replace single-use plastic. Many companies are guilty of greenwashing and dubious claims of carbon neutrality, yet there’s a growing trend of refillable products that may result in measurable sustainability.

The direct-to-consumer brand Wild Refill Deodorant sends an aluminum and recycled plastic applicator, and the deodorant refills come wrapped in a biodegradable bamboo paper. Subscribers are sent refills in simple corrugated cardboard packages. Rihanna’s Fenty Skin also uses refillable containers, helping to eliminate single-use plastic in an industry that relies on it.

For an even bigger step to plastic-free living, Loop delivers a wide selection of products—from cosmetics and household goods to baking essentials and ice cream—in refillable zero-waste containers. It’s sort of like buying at the neighborhood grocery co-op using your own glass and metal containers, but Loop picks up, washes, and reuses the empties. In the past few years, this model has resprouted on a local level. In most major US cities, you can find stores—sometimes called “refill stations”—that only offer refillable products.

Minimal Packaging for Maximum Protection

We’ve been trained to believe the only way to protect fragile products is styrofoam and packing peanuts. In an increasingly competitive market, every cost-saving measure could be the difference between making a profit, breaking even, or worse. In other words, plastic-based protection can be cheaper. But two factors are challenging this reality.

First, many sustainable packing peanut alternatives are widely available, including some made from corn. An expertly engineered structure is perhaps more sustainable. While it may cost more design money up front, the long-term savings for your company and the planet are worth it. Rather than a large box filled with air cushions, styrofoam, or packing peanuts, packaging engineers can design a much smaller—and significantly stronger—structure using only cardboard. Many brands are turning to home appliances packaging and cosmetic packaging designs made from cardboard rather than styrofoam.

Olive Oil Jones, purveyors of ultra-fresh, geographically specific olive oil, did just that. Bottle-shaped cardboard layers and strategic cardboard air pockets cradle olive oil and vinegar all over the world. The company now fulfills their orders faster and saves money with more compact shipments with a significant reduction in breakage. As brands shift to e-commerce, they will allocate more resources to efficient and sustainable packaging design. This means it’s becoming increasingly important to focus on putting together e-commerce packaging solutions that prioritize long-term sustainability.

If you want to know more about Zenpack’s services

Let our packaging consultants help you turn your idea into reality.