Experimentation is the core of our creative process. We leverage rapid prototyping for packaging to develop sample after sample, resulting in expertly engineered packaging. In our package prototype development cycle, a crucial aspect of our packaging consulting services, we test, tweak, and improve with every cut and fold. You may already have a complete dieline, or just the start of an idea. No matter where you are in the process, our team will work with you to develop fast product package prototypes.

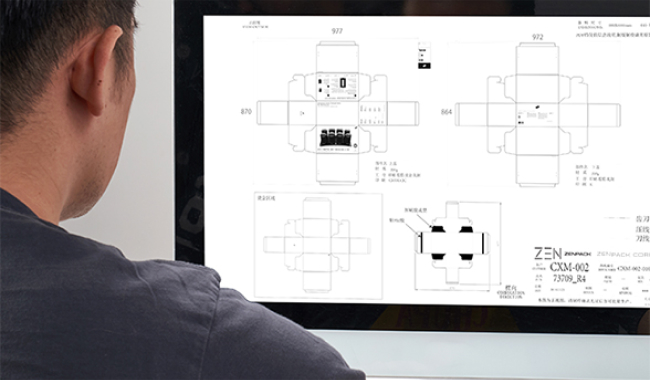

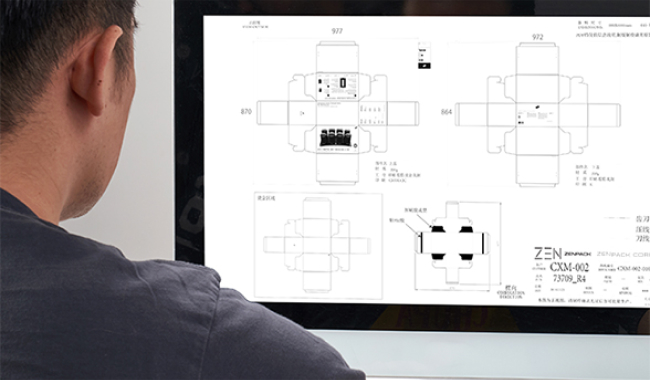

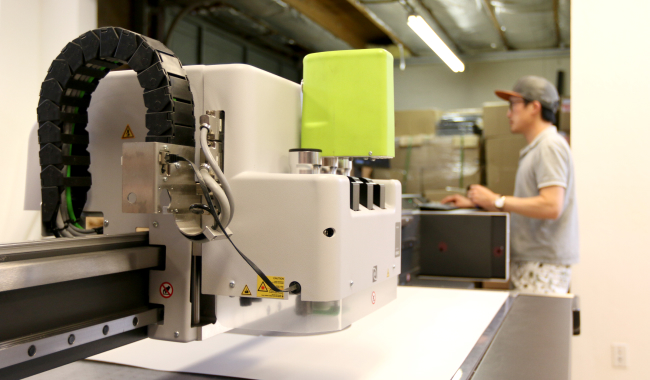

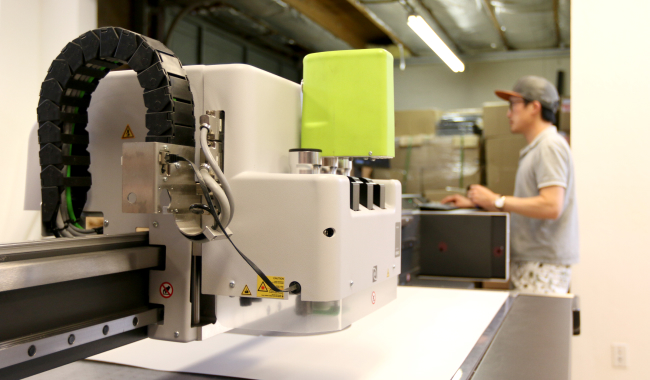

Our Design Lab is outfitted with the ESKO Kongsberg X22 cutting table, a state-of-the-art finishing device for flexible packaging prototypes. The Kongsberg allows us to produce and ship mock prototypes within 24 hours. Rather than waiting weeks or months, you’ll have something in your hands shortly after the dielines are drawn. The Kongsberg allows us to explore and further develop interesting prototype packaging designs without compromising quality. That means your products go into production faster, and hit the shelves sooner. Our packaging engineering services encompass a dedicated team of engineers and machine technicians who specialize in transforming dielines into full-scale prototypes. Every 3D rapid prototype starts with a 2D digital dieline. Companies often send their dielines ready to print. They may have their own structural engineering team, or work with an outside agency. In these cases, it’s a simple as converting the dielines to 3D CAD files (computer-aided design), making a few adjustments, and starting the cutting table. In other cases, we start from scratch. Our creative strategists and packaging engineers collaborate on designs based on the product and client needs. We design a digital package design mockup and dielines, then hit the work tables. The Kongsberg cutting table comes with a wide range of tools to cut all types of materials, including corrugated cardboard, solid board, foam, and even wood. It makes cuts and perforations on a large scale, allowing us to assemble mock prototypes in minutes. Powerful yet precise, the Kongsberg has excellent print-to-cut registration, making it a versatile machine for all types of applications. When the prototype is ready for review, we meet with you and your team to discuss modifications and refinements. No adjustment is too small. We pay close attention to folds, enclosures, and lids to ensure that no space is wasted. These seemingly tiny details affect shipment and protection, but most importantly, the unboxing experience. Once the final prototype is approved, we move onto branding, ISTA-testing, and the golden sample. When we say rapid, we mean it. We have the machines, experience, and personnel to quickly produce 3D packaging prototypes. In the age of e-commerce, time is of the essence, and each day counts when launching a new product to market. As an expert provider of e-commerce packaging solutions, we understand that the best way to evaluate a packaging idea is by feeling it in your hands. Taking the time to produce a 3D printed packaging prototype gets your product to market faster. Rapid prototyping is inherently iterative. It takes more than one version to achieve the desired results. That may sound like more time, but our packaging engineers can adjust dielines instantly. Iterative design also reduces mistakes and flaws, which saves time and money in the future. Companies who skip the rapid prototyping process often need to redesign their packaging and tooling after the product has already gone to market. We’ve designed our package prototype development process to save on time, costs, and materials. As a sustainable packaging design agency, we curate an on-site library of sustainable materials that’s ready to supply any packaging idea. We can also produce your 3D prototype packaging designs in the United States or Southeast Asia depending on your location. Flexible production cuts down on shipping time and costs, resulting in faster prototypes and more sales. We’re proud of our diverse experience. Our packaging engineers, creative strategists, and graphic designers have created packaging prototypes for every type of company, from consumer electronics and home appliances to cannabis packaging and influencer packaging. They’re experts in sustainable design; not only with materials, but developing the most efficient dielines for shipping and protection. Our structural designers are also product designers. They know the principles of good brand packaging design and apply their knowledge to innovate products. Driven by our core belief—packaging is part of the product—they produce prototypes that are logical extensions of your product and brand. Our team collaborates across time zones and supply chains to quickly deliver mock prototypes. If your product requires ISTA testing or other certifications, we can simultaneously produce a prototype in Southeast Asia to streamline validation. Our factories use the same machines and materials to guarantee quality and packaging integrity. It’s a 24-hour cycle we leverage to save you time and money. No matter the company size or status, we produce every prototype on the same cutting table. That means we only produce premium packaging prototypes. Even if it’s your first product, the packaging prototype receives the same expert service as major brands. We’re a small team with international reach, so we’re dedicated to providing excellent customer service and support. We’re not just a design agency, or a packaging manufacturer, or a logistics company. Zenpack is all three—as well as a packaging prototype company. Our capabilities inform every packaging prototype. If a structure doesn’t protect the products in transit, the prototype needs refinement. If a certain material prints a more vibrant color to match your style guide, our manufacturing team will calibrate their printers for that surface. We design for every moment in the packaging journey. Rapid Prototyping for Packaging

Cutting-edge Rapid Prototyping Services

Our 3D Rapid Prototyping Process

Dieline Development

Cutting & Folding

Reviewing & Refining

Product Package Prototypes Delivered Fast

A Team of Packaging Prototype Design Experts

Why Work with Zenpack?